Cargo Systems

Air Cargo Systems

Alpine Systems Associates specializes in Air cargo systems, which are specialized equipment designed to facilitate the efficient handling, storage, and transportation of goods transported by air. These systems are crucial in air freight logistics, ensuring that cargo is moved swiftly, safely, and accurately through various stages of the supply chain. ULDs (Unit Load Devices) are containers or pallets used to consolidate cargo for transportation. ULDs are assembled in Air cargo facilities and moved on cargo systems, including caster decks, fiberglass decks, roller conveyors, and roller beds. ULDs are moved from the Airplane to warehouse cargo systems to roller bed trucks. Without cargo systems, ULDs must be handled with forklifts, which is inefficient, unsafe, and could lead to damage to the ULD. Cargo systems are often integrated with scales, X-ray machines and CT scanners for screening cargo to ensure security compliance. Often, Air Cargo lifts must be used to bridge the difference in height between Air cargo dollies and slave pallets, which are used to move ULDs from the Airplanes to the Cargo warehouse.

These components work together to streamline the movement of air cargo, from the moment it arrives at the warehouse until it is loaded onto an aircraft and eventually delivered to its destination. Air cargo systems play a vital role in supporting global trade, ensuring that goods are transported quickly and efficiently across international borders.

Installing cargo handling systems at air cargo warehouses offers several advantages, including:

Increased Efficiency:

Automated and well-designed cargo handling systems streamline the process of loading and unloading cargo, reducing the time required to move goods through the warehouse. This leads to faster turnaround times and increased throughput.

Enhanced Safety

Modern cargo handling systems are designed with safety in mind. They minimize the need for manual lifting and handling, reducing the risk of injury to employees. Cargo systems reduce a facility's reliance on forklifts, increasing overall safety. Additionally, features like slip-resistant surfaces and automated lifting mechanisms further enhance workplace safety.

Cost Savings

While the initial investment in cargo handling systems can be significant, the long-term savings are substantial. Reduced labor costs, lower maintenance requirements, lower equipment/forklift costs, and fewer workplace injuries contribute to overall cost savings.

Scalability

Cargo handling systems can be easily scaled and adapted to accommodate changing business needs. As the volume of cargo increases, the system can be upgraded or expanded to handle the additional load without significant disruptions.

Better Utilization of Space

Advanced cargo handling systems are designed to optimize warehouse space, allowing for more efficient storage and retrieval of goods. This maximizes the use of available space and can delay or eliminate the need for physical expansion of the warehouse.

Reduced Manpower Requirements

With automated systems, the need for manual labor is reduced, which can help address labor shortages and reduce dependency on a large workforce.

Fiberglass Cargo Systems

Our versatile fiberglass cargo system utilizes fiberglass grating and ball transfer units. These fiberglass systems are more flexible and less expensive than traditional steel cargo systems. Fiberglass systems can be easily modified to adjust to a company's changing needs.

Fiberglass offers superior corrosion resistance, a lighter weight, and greater flexibility compared to steel, making it ideal for environments where durability and ease of handling are crucial. In the event of damage, fiberglass panels can be easily replaced, whereas damaged steel is rigid and must be cut out and rewelded.

The fiberglass grating provides a highly visible, slip-resistant walking surface to ensure employee safety. Additionally, fiberglass grating is corrosion- and impact-resistant, lightweight, and heavy metal-safe. Our fiberglass system can be used for a variety of markets and applications, such as air cargo, distribution centers, warehouses, storage facilities, and any applications where air cargo containers are handled.

The main advantages of the fiberglass system over steel include:

-

Less expensive than Steel system

-

A safe working area for employees

-

Continuous movement of inventory

-

Reduced manpower and equipment needs

-

A versatile system for your company’s changing needs

-

Durability and low maintenance

Steel Cargo Systems

A steel air cargo deck is a specialized platform used in air cargo handling facilities to streamline the movement, loading, and unloading of air cargo. These decks are designed with integrated steel casters or ball transfer units (BTUs) that allow for the easy multidirectional movement of Unit Load Devices (ULDs) and other cargo containers. Steel cargo decks are comprised of Heavy-Duty Construction made from robust steel to support the weight of heavy cargo and withstand the rigors of frequent use. These systems are durable and long-lasting, providing a reliable platform for cargo handling operations. The systems facilitate the smooth and effortless transfer of cargo containers across the deck. Often designed in modular sections that can be assembled or reconfigured to fit the specific layout of the warehouse or cargo handling area. Cargo decks have a slip-resistant Surface, enhancing safety for workers, and are constructed from corrosion-resistant materials, reducing the need for frequent maintenance and repairs.

Advantages of Steel Caster Decks :

-

Enhanced Efficiency: Significantly reduces the time and effort required to move cargo containers, speeding up the loading and unloading process. Increases overall throughput in cargo handling operations.

-

Improved Safety: Minimizes the need for manual handling of heavy cargo, reducing the risk of injury to workers. A stable and secure platform for handling cargo, preventing accidents and damage to goods.

-

Cost Savings: Durable construction leads to a longer lifespan and fewer replacements, saving costs in the long run. Reduces labor costs by minimizing the need for manual handling and the associated workforce.

-

Versatility: Suitable for a wide range of cargo types and weights, making it a versatile solution for various air cargo handling needs. It can be used in different areas of the warehouse, including loading bays and staging areas.

-

Scalability: Modular design allows for easy expansion or reconfiguration, enabling the deck to adapt to increasing cargo volumes or changes in warehouse layout. It can be tailored to fit specific operational requirements.

-

Low Maintenance: Easy to clean and maintain, ensuring long-term usability.

-

Enhanced Cargo Handling: Facilitates the smooth and precise positioning of ULDs and cargo containers, reducing the risk of damage during handling. Provides a stable and level surface for cargo operations, ensuring the safe transfer of goods.

-

Operational Flexibility: Can be integrated with other cargo handling systems, such as conveyor belts and Air Cargo Lifts, for a seamless logistics workflow. Supports various operational strategies, from manual to semi-automated processes.

Overall, steel caster air cargo decks provide a robust, efficient, and safe solution for handling air cargo. Its features and advantages make it an essential component in modern air freight logistics, contributing to improved operational performance and cost-effectiveness.

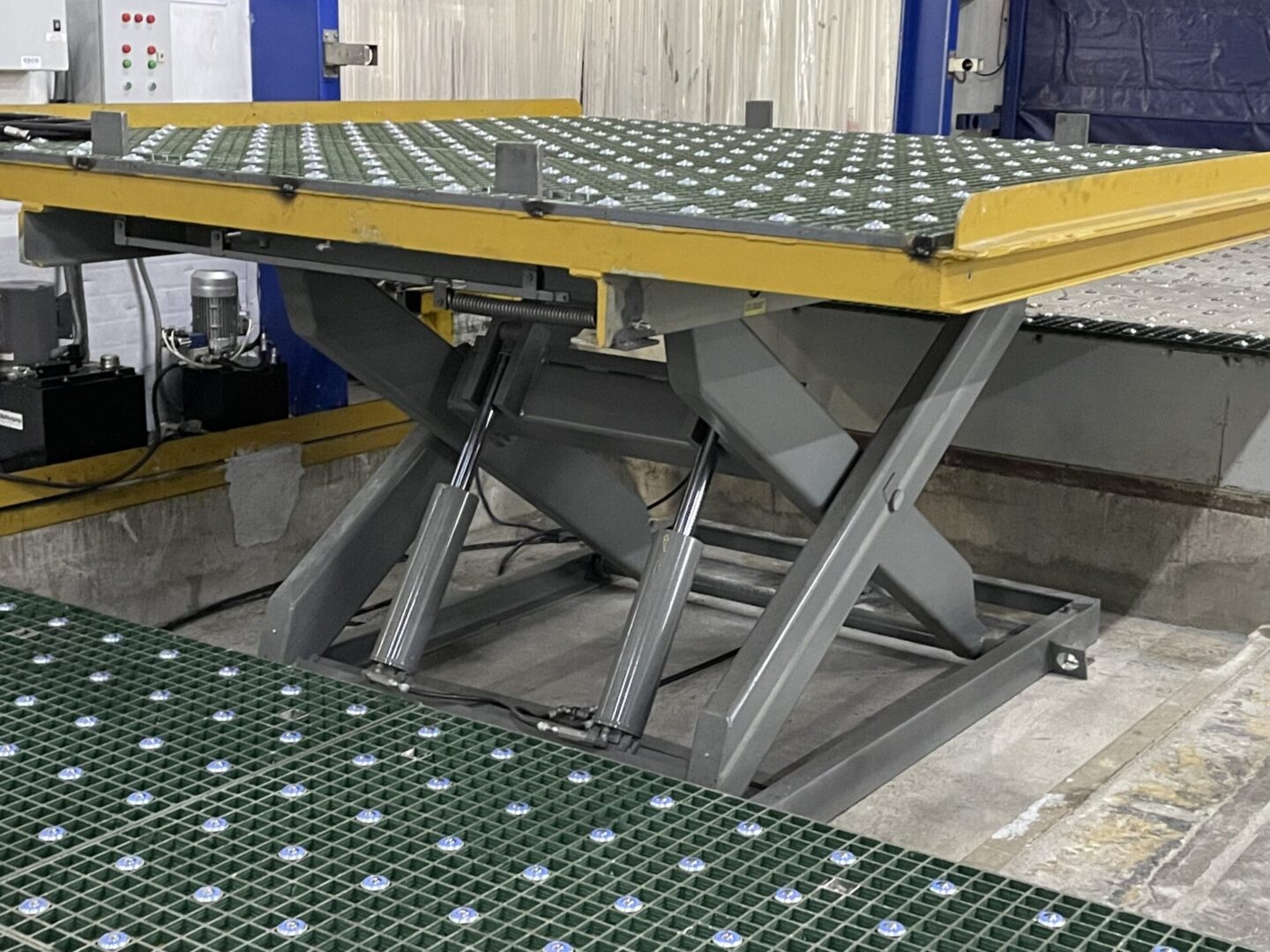

Cargo Lifts

Air Cargo Lifts are high-capacity, heavy-duty scissor lifts designed for the transfer of loads between transport vehicles, cargo terminals, and warehouses, which are typically set at different heights. The standard platform of an air cargo lift features inverted casters or ball transfer units (BTUs), allowing cargo containers and Unit Load Devices (ULDs) to be easily maneuvered in any direction.